From "tooling" to "smart tooling", see how fixtures support the precision future of Chinese manufacturing

In today's global manufacturing competition entering the "micrometer level", high-end CNC machine tools, industrial robots and other "star equipment" often dominate the industry headlines. But few people have noticed that in scenarios such as spacecraft engine blade processing, semiconductor lithography machine component assembly, and welding of new energy vehicle battery modules, a seemingly ordinary set of fixtures (tooling fixtures) is quietly becoming a key variable determining manufacturing accuracy. As China's high-end manufacturing industry accelerates its breakthrough towards intelligence and precision, the traditional manufacturing tool of fixtures is undergoing disruptive innovation, and the resonance effect between its technological leap and industrial upgrading is becoming increasingly prominent.

1、Precision Revolution: The Technological Upgrade Path of Modern Fixtures

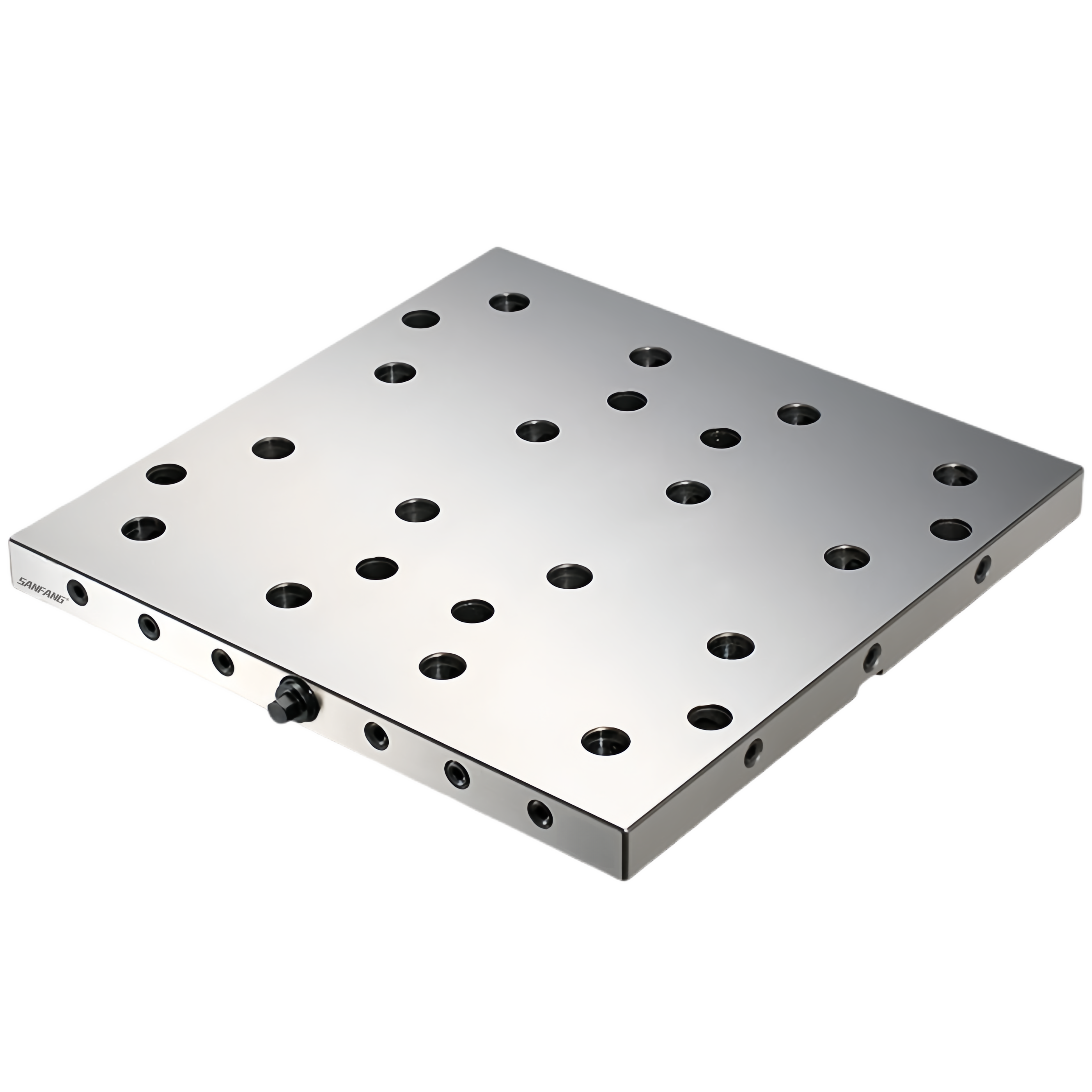

In traditional manufacturing, fixtures mainly perform the basic function of fixing workpieces, but in high-end manufacturing, their role has evolved into a "process data hub". Taking the processing of titanium alloy wing beams for the domestically produced C919 aircraft as an example, each set of aviation structural components weighing 2 tons needs to be milled with a precision of 0.01 millimeters on a five axis linkage machine tool. The dedicated hydraulic fixture not only needs to withstand a spindle vibration of 20000 revolutions per minute, but also needs to sense and compensate for errors caused by material thermal deformation in real time. This type of intelligent fixture equipped with pressure sensing and temperature compensation system has increased the stability of machining accuracy by 40%.

According to data from international fixture giants SCHUNK and AMF, the global high-end fixture market will exceed $38 billion in 2023, with smart fixtures equipped with IoT interfaces and adaptive adjustment capabilities growing at a rate of 28%, far exceeding the industry average. In the Chinese market, domestic enterprises represented by Suzhou Maixing Technology and Dongguan Sufeng Precision have achieved an import substitution rate of over 60% in the fields of 3C electronics and medical equipment through independent research and development of innovative products such as magnetic levitation flexible fixtures and laser assisted positioning systems.

2、The 'pivot effect' of industrial upgrading: fixture driven manufacturing paradigm transformation

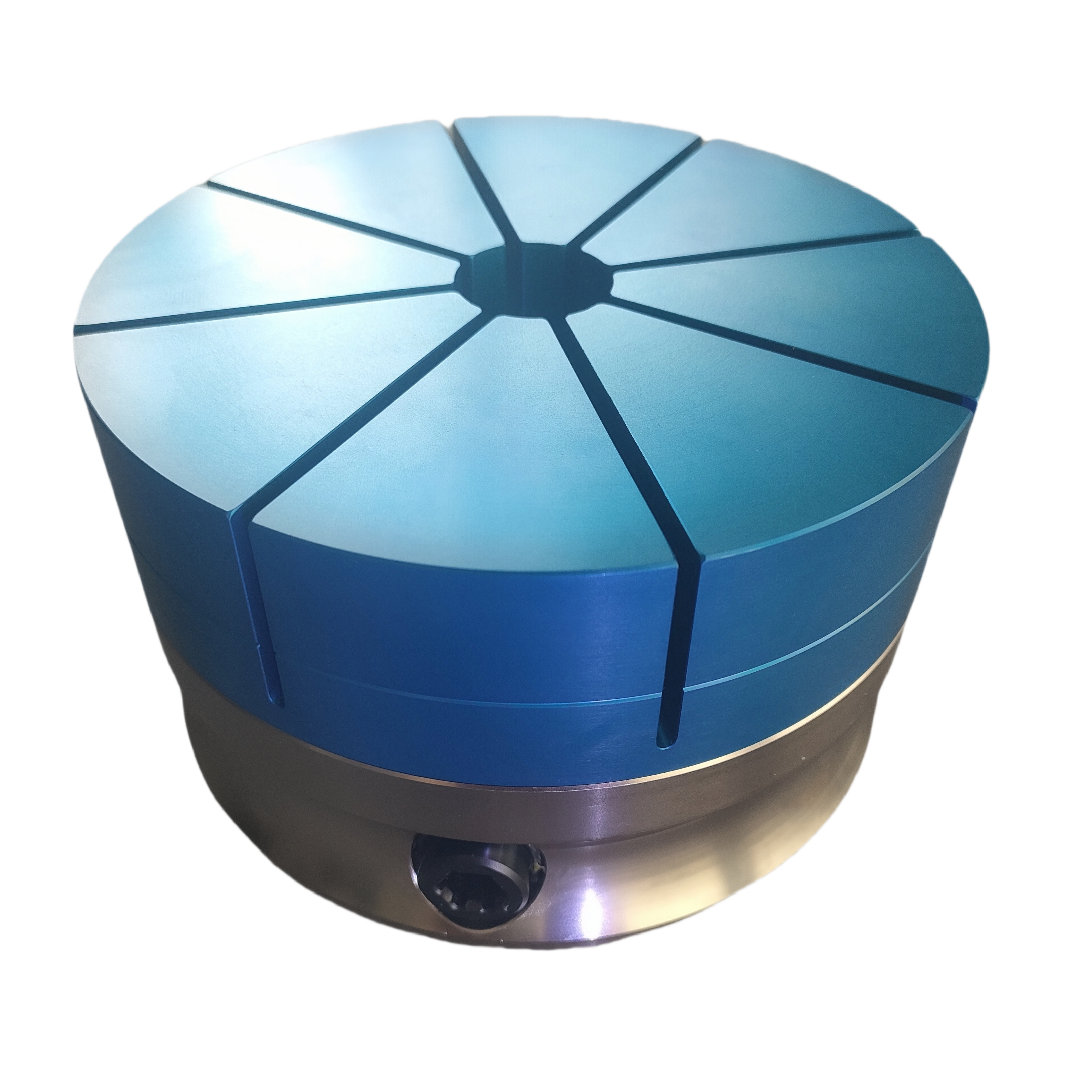

Against the backdrop of explosive growth in the new energy vehicle industry, flexible innovation in fixtures is reshaping production logic. In the battery pack production line of Tesla's Shanghai Gigafactory, modular combination fixtures can complete the production line switch from Model 3 to Model Y within 15 minutes, saving 90% of the changeover time compared to traditional fixtures. This "plug and play" fixture design increases the compatibility of single production line models by 5 times, directly supporting Tesla's "three-day two model" hybrid production mode.

Deeper changes occur at the level of technological collaboration. The i5 intelligent fixture system jointly developed by Shenyang Machine Tool and Huazhong CNC integrates fixture status data into the digital twin platform, achieving predictive compensation for machining errors. In the Dongfeng Lantu high-end electric vehicle chassis welding workshop, the clamping force and positioning data of each fixture are exchanged in real-time with the MES system through 5G network, which has increased the welding yield from 92% to 99.5%. These practices confirm that modern fixtures have transformed from physical tools to data nodes, driving the manufacturing system towards a closed-loop evolution of "perception analysis decision".

3、Breaking through the bottleneck of precision manufacturing: the battle against domestic fixtures

Despite significant progress, China still faces severe challenges in the field of ultra precision fixtures. The workpiece stage vacuum fixture used in EUV lithography machines needs to meet the requirement of 0.1 nanometer flatness and maintain material stability in extreme vacuum environments. These products still rely on exclusive supplies from companies such as VDL in the Netherlands. Similarly, in the processing of fuel valve bodies for satellite thrusters, ceramic composite fixtures that can simultaneously achieve micro level force control and withstand high temperatures of 2000 ℃ are currently only available in mass production by three companies worldwide.

Faced with technological barriers, domestic industry university research forces are accelerating collaborative research and development. The quantum dot sensing fixture developed by the Department of Mechanical Engineering at Tsinghua University in collaboration with the 14th Institute of China Electronics Technology Group Corporation (CETC) has achieved internationally leading accuracy in detecting clamping errors of micrometer sized parts by implanting nanoscale strain sensors. At the policy level, the "14th Five Year Plan for the Development of Intelligent Manufacturing" has listed "intelligent process equipment" as a key project for the first time, and many local governments have set up special funds to support the research and development and manufacturing of precision fixtures. This dual wheel drive of "national strategy+market demand" is nurturing a group of specialized and innovative enterprises such as Ward Precision and Hexacon.

4、Future vision: intelligent transition from tools to ecology

Industry experts predict that the next breakthrough in fixture technology will focus on three dimensions: first, material innovation. Silicon nitride ceramics and metal based composite materials will significantly improve the durability and environmental adaptability of fixtures; Secondly, AI empowerment will enable deep learning algorithms to achieve autonomous optimization of fixture parameters; The third is service extension, and the fixture health management system based on digital twins is expected to create a billion dollar after-sales service market.

More imaginative is the construction of a modular fixture ecosystem. Festo, Germany has launched a "LEGO style" fixture platform that supports cloud configuration. Users can combine pneumatic, hydraulic, and electromagnetic units online according to their processing needs. This model is being implemented in China - the fixture resource sharing system launched by Haier's industrial Internet platform enables small and medium-sized manufacturing enterprises to use high-end fixtures in the form of leasing, which improves equipment utilization by three times and reduces initial investment costs by 60%.