Against the backdrop of accelerating the transformation of global manufacturing towards intelligence and high-end, machine tool fixtures, as the core process equipment in the field of mechanical processing, are undergoing disruptive technological changes. The concentrated appearance of innovative achievements such as multi axis linkage flexible fixtures, intelligent sensing adaptive systems, and carbon fiber composite material fixtures from the Hanover Industrial Exhibition in Germany to the China International Machine Tool Exhibition marks that this traditional industry is standing at the starting point of a new round of industrial upgrading.

1、The wave of intelligence: a leap from mechanical clamping to intelligent perception

On the production line of a new energy vehicle parts enterprise in Zhejiang, a five axis machining fixture equipped with a visual recognition system is automatically adjusting the clamping angle. Faced with different types of motor housings, the system uses AI algorithms to analyze 3D scanning data in real time, controlling the positioning accuracy within 0.005 millimeters and reducing the product defect rate from 1.2% to 0.3%. Behind this is the vivid practice of intelligent fixture technology moving from the laboratory to industrial scenarios.

According to the International Machine Tool and Fixture Association (IMWA) 2023 report, the global smart fixture market has reached a size of 4.8 billion US dollars, with a compound annual growth rate of 15.7%. The core breakthroughs focus on three major areas: the dynamic compensation system embedded with strain sensors can sense changes in cutting force in real time; Integrated industrial Internet of Things (IIoT) fixtures can actively upload device health data; The virtual debugging technology based on digital twins shortens the fixture design cycle by 60%.

The latest NeuroGrip series products launched by Okuma Machinery in Japan have achieved self-learning optimization of clamping force through neural network algorithms. The system continuously collects vibration, temperature, deformation and other data during the processing, dynamically adjusts the clamping strategy, and reduces the deformation of thin-walled parts by 42%. This' thinking fixture 'is redefining the standard for process stability.

2、Flexible Revolution: Modular Design Breaks the Difficulties of Multi Variety Production

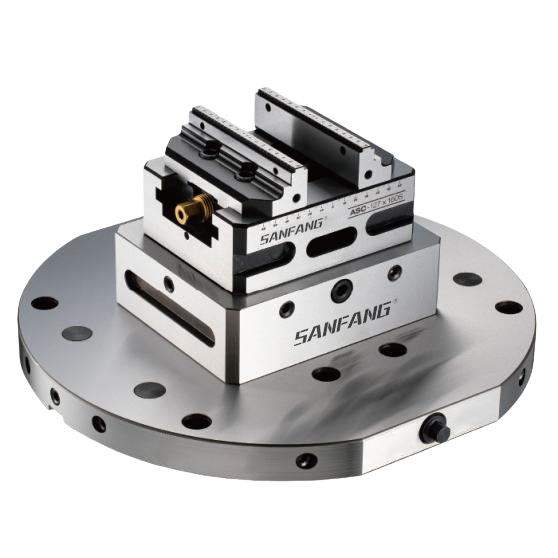

In the aerospace industry, a certain aircraft manufacturer is facing the challenge of cross material processing from aluminum alloy frames to titanium alloy load-bearing components. After adopting modular quick change fixtures from German company Schalke, the tool switching time was reduced from 4 hours to 15 minutes, and the inventory of fixtures decreased by 70%. This LEGO style solution, consisting of a basic platform, functional modules, and intelligent interfaces, is becoming a standard in the field of discrete manufacturing.

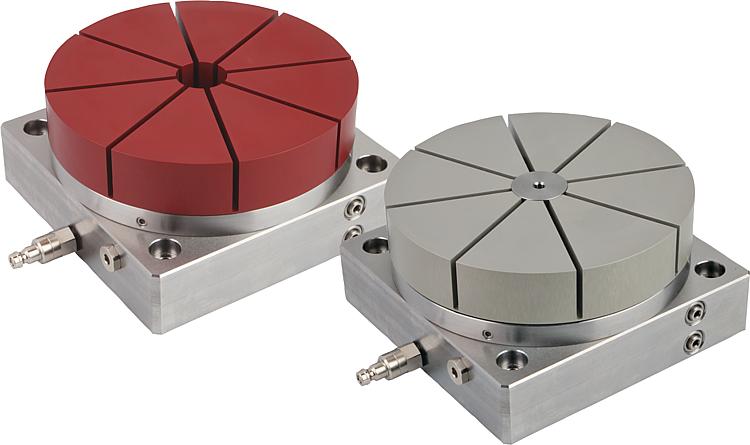

The deepening of modular design concept has given rise to two major innovative directions: in terms of standardization, the ISO/TC39 working group is developing a globally unified fixture interface standard, and the fourth generation modular system expected to be released in 2025 will achieve cross brand compatibility; In terms of functional expansion, EROWA Switzerland has launched a magnetic coupling module that allows for quick combination of various clamping units such as vacuum suction cups, hydraulic calipers, and pneumatic top pins on a single base.

Chinese fixture companies are also accelerating their pursuit. The "Magic Cube" series of flexible fixtures developed by a certain enterprise in Suzhou, through topology optimization design, enables a single module to have the ability to expand hexahedral functions, and has been successfully applied to multi variety mixed line production in the 3C electronics industry, helping customers improve changeover efficiency by 300%.

3、Innovation in Materials and Processes: A Dual Breakthrough in Lightweight and Sustainable Manufacturing

At the laboratory of the University of Stuttgart in Germany, researchers are testing machine tool fixtures made of carbon fiber reinforced ceramic matrix composites (CMC). Compared to traditional alloy fixtures, this material has a 5-fold increase in specific stiffness and an 80% decrease in thermal deformation coefficient, making it particularly suitable for the processing of high-precision optical components. Although the current cost is 8-10 times that of steel fixtures, its market prospects are widely optimistic with the surge in demand in the aerospace and semiconductor fields.

The lightweight technology route presents diversified development: the metal lattice structure weight reduction technology developed by Kennametal in the United States uses 3D printing to manufacture internal honeycomb fixtures, achieving 50% weight reduction while ensuring rigidity; THK in Japan adopts gradient material design, using hard alloy in the clamping part and aluminum alloy for the support structure, balancing strength and economy.

Green manufacturing requires promoting technological innovation. The latest EU directive on ecological design of machine tools explicitly requires a 40% reduction in carbon emissions during fixture manufacturing processes by 2030. The powder metallurgy near net forming process launched by Sandvik in Sweden has increased the material utilization rate from 35% in traditional cutting processing to 92%, and reduced the energy consumption of each fixture manufacturing by 65%.

4、Service model transformation: from product delivery to full lifecycle management

Under the catalysis of industrial Internet, the business model of fixture enterprises is undergoing a fundamental change. The "Clamping as a Service" platform launched by HAINBUCH, a German company, provides customers with value-added services such as preventive maintenance, performance optimization, and residual value recovery by monitoring the status data of 23000 sets of in use fixtures worldwide in real time. Its service revenue proportion has jumped from 12% in 2018 to 41% in 2023.

This transformation has reshaped the industry value chain: upstream enterprises have begun to provide solutions that include process consulting, fixture selection, and processing validation; Midstream manufacturers achieve remote debugging through digital twin technology; Downstream users can reduce their initial investment by adopting a pay per use model. The i5 intelligent fixture cloud platform launched by Shenyang Machine Tool has provided shared fixture services to more than 300 small and medium-sized manufacturing enterprises, reducing customers' fixed assets investment by 60%.

5、 Future challenges and strategic opportunities

Despite the bright prospects, the industry still faces three challenges in its development: firstly, the interdisciplinary talent gap continues to widen, and there is a scarcity of composite engineers who understand both mechanical design and algorithm development; Secondly, data security and standardization issues constrain the interconnectivity of smart fixtures; Furthermore, key materials and core sensors still rely on imports, with a localization rate of less than 30%.

In response, leading companies in the industry have launched strategic layouts: Mitsubishi Heavy Industries, in collaboration with the University of Tokyo, has established an intelligent fixture research institute, focusing on the development of high-precision displacement sensor technology; The "Action Plan for Innovative Development of High end CNC Machine Tools" released by the Ministry of Industry and Information Technology of China clearly states that by 2025, the localization rate of high-end fixtures should reach over 70%; The Fraunhofer Institute in Germany is leading 12 national institutions to promote the development of international standards for "Fixture 4.0".

Standing at the intersection of a new round of industrial revolution, high-end machine tool fixtures are moving from behind the scenes to the forefront. This field, once regarded as "industrial supporting role", has now become an important yardstick to measure the competitiveness of national manufacturing industry. With the continuous penetration of technologies such as 5G, artificial intelligence, and new materials, future fixtures will not only be positioning devices in the physical world, but also become intelligent nodes connecting digital twins, process optimization, and energy efficiency management, providing key support for the transformation and upgrading of the global manufacturing industry.